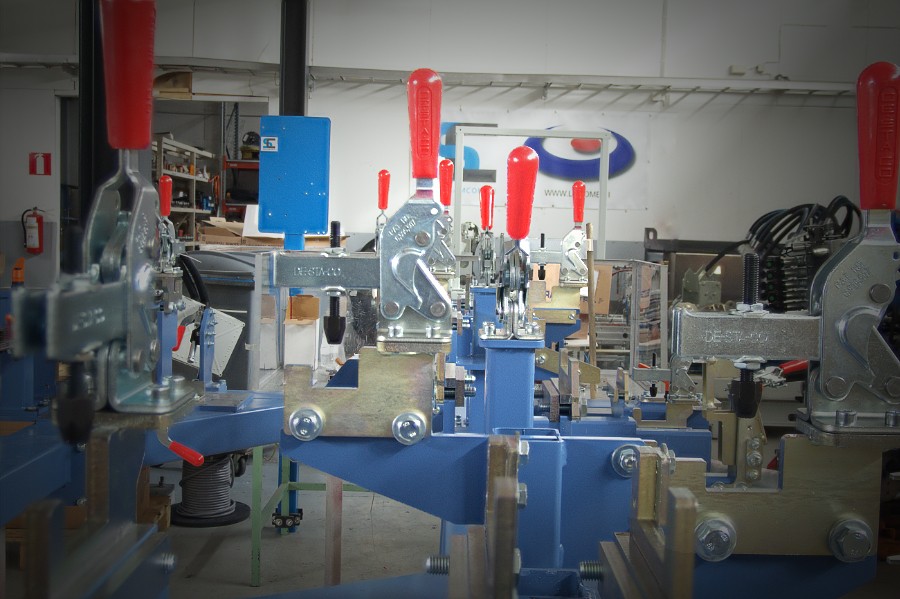

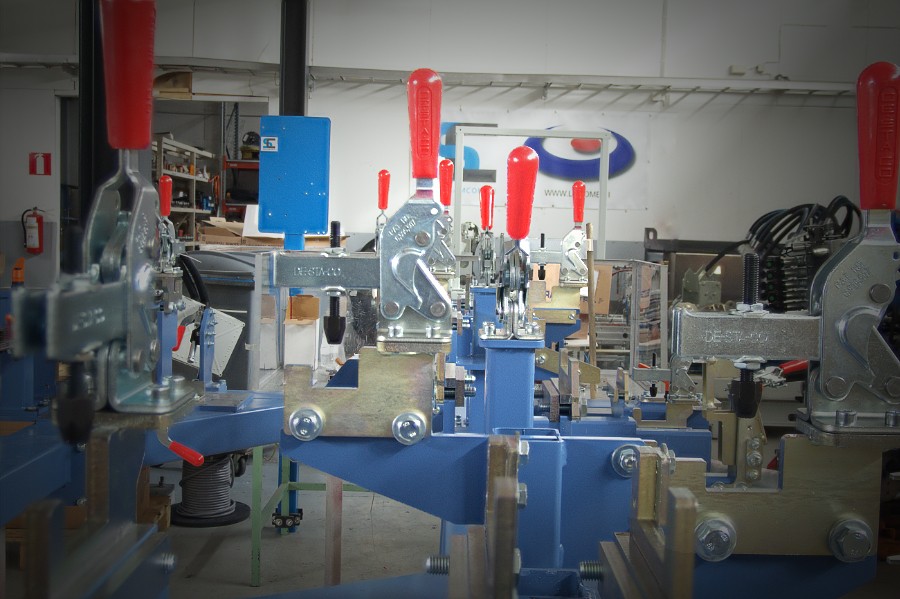

Assembly and welding equipment

Using assembly equipment, lifting equipment and welding equipment in assembly work enhances efficiency, increases product quality and improves occupational safety.

Using assembly equipment, lifting equipment and welding equipment in assembly work enhances efficiency, increases product quality and improves occupational safety.

We design, build and deliver ready-made assembly, welding and lifting equipment to our partners. Our production-ready and tested production equipment is ideal for all types of assembly work. For example, Scania buses are built with Lakome’s assembly equipment, and our lifting equipment is used at numerous facilities.

Assembly equipment can be used to position the assembled parts more accurately and quickly and to carry out the installation. The use of assembly, welding and lifting equipment lets you efficiently work on different parts.

Different pieces of assembly equipment make it possible to assemble the product with tighter tolerances. This enables a more precise production process, leading to enhanced product quality and workmanship.

Assembly and lifting equipment enable the handling of heavy products in a controlled and safe manner. This reduces the risk of work-related accidents.

Click the button on the right and let’s get rolling.

We supply assembly and welding equipment to prominent European machine and equipment manufacturers. In this context, welding equipment does not refer to equipment used to weld metal, but to equipment used to hold large parts in place during the welding process. Our equipment is used for applications such as tractor assembly and the welding, equipping and assembling of bus body structures. We always apply for the CE marking for any devices we implement.

Assembly, lifting and welding equipment are important tools in modern industrial production processes. They can be used to quickly, efficiently and accurately manufacture different types of components and assemble them into functional, high-quality products. They also enable precision machining and provide perfect control during the processing, ensuring a high-quality and durable end result. The tyre lift in the picture ensures a safe and quick installation of heavy vehicle tyres on the production line.

In industry, the use of assembly and welding equipment provides many advantages. They can be used to speed up the production process and boost production efficiency. The accuracy and speed of the equipment also minimise the potential for errors and improve production quality. The equipment can also be used to easily manufacture more unusual and complex products, which provides a competitive edge and enables the development of new products.

Another significant advantage is the improvement of safety. Assembly, lifting and welding equipment is designed and manufactured to meet all safety requirements. It can reduce people’s exposure to dangerous situations and help minimise the risk of accidents. This, in turn, improves the well-being of employees.

The use of assembly, lifting and welding equipment is also an environmentally friendly choice for industries. Efficient use of equipment reduces unnecessary work and saves raw materials, which reduces the company’s environmental load. This type of use also reduces energy requirements and enhances the company’s energy efficiency.

In summary, the use of assembly, lifting and welding equipment provides numerous advantages and strengths for companies across industries, including faster and more efficient production, improved safety, eco-friendliness and the opportunity to develop new products.

Let’s have a meeting. We’re Here to Help you.