Successful projects in different industries

Over the years, we have carried out countless successful projects. Check out our references from different industries below!

Lakome industrial equipment supplier

Lakome is industrial equipment supplier

Etusivu • References

Over the years, we have carried out countless successful projects. Check out our references from different industries below!

Over the years, Lakome has delivered hundreds of solutions to different industries. We have built our expertise and provided our partners with solutions for the most challenging conditions. Our solutions have a wide-range of applications in various industries, including tractor, bus, and train manufacturing, the explosives industry, mining, wood processing, consumer packaged goods industry and materials handling.

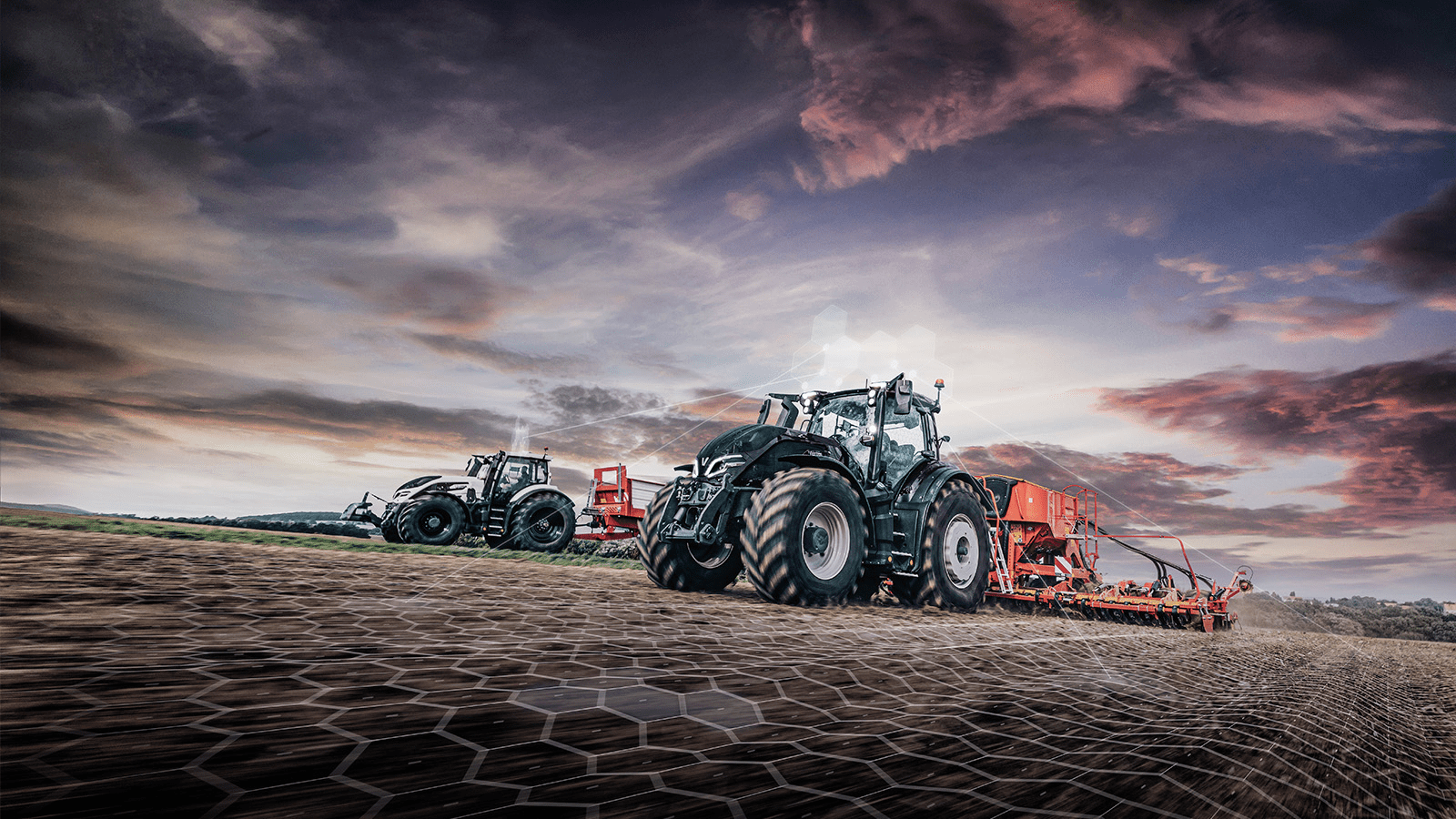

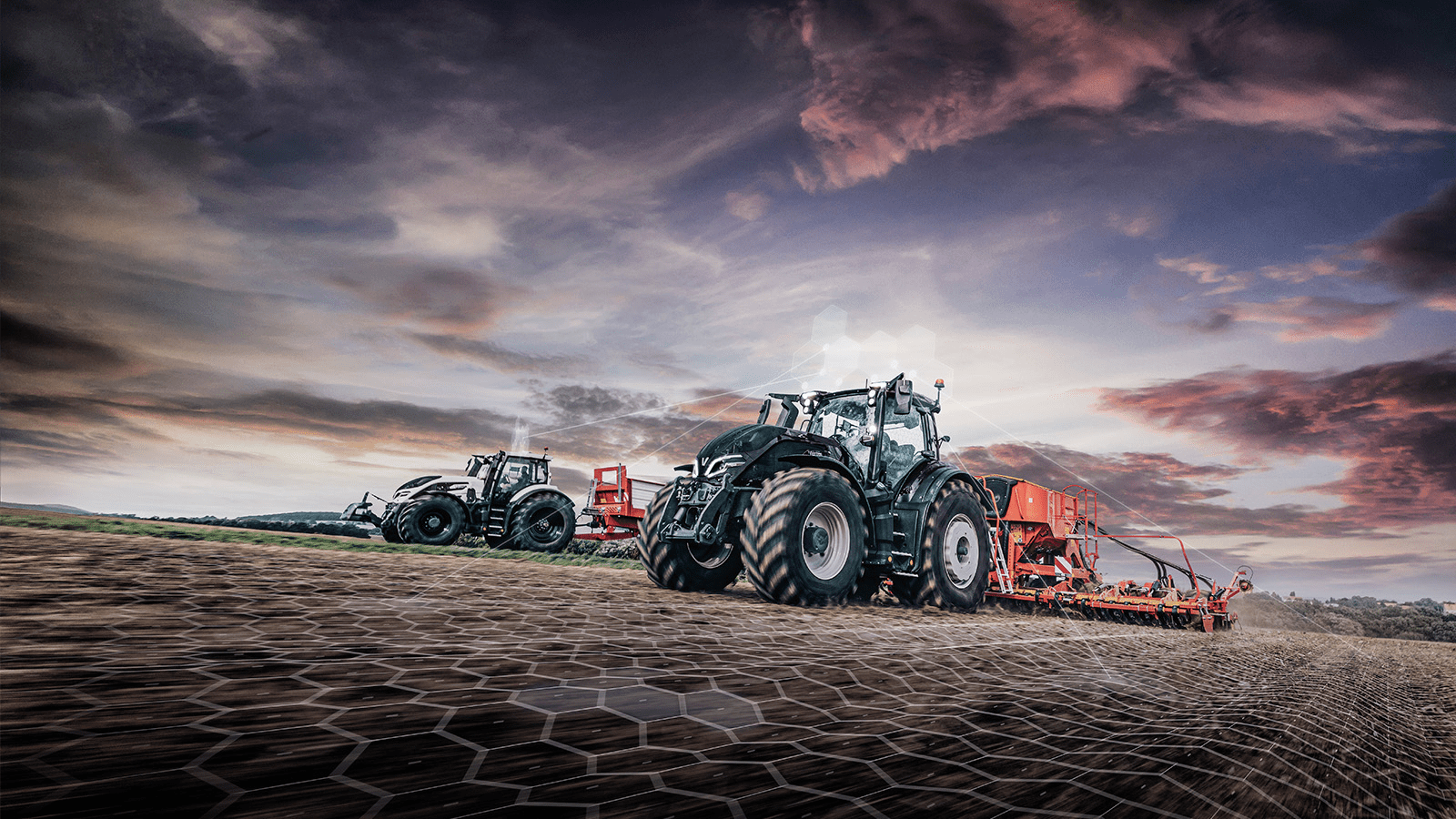

When you see a Valtra tractor in action, it includes both visible and hidden parts that have been installed or tested using Lakome equipment. When you travel on a Scania bus in Europe, its body is assembled with equipment manufactured by Lakome. Lakome is responsible for numerous tools that you encounter both during your daily routines and free time. But as much as we’d like to share all our secrets, some must remain a mystery.

Reference articles are in Finnish.

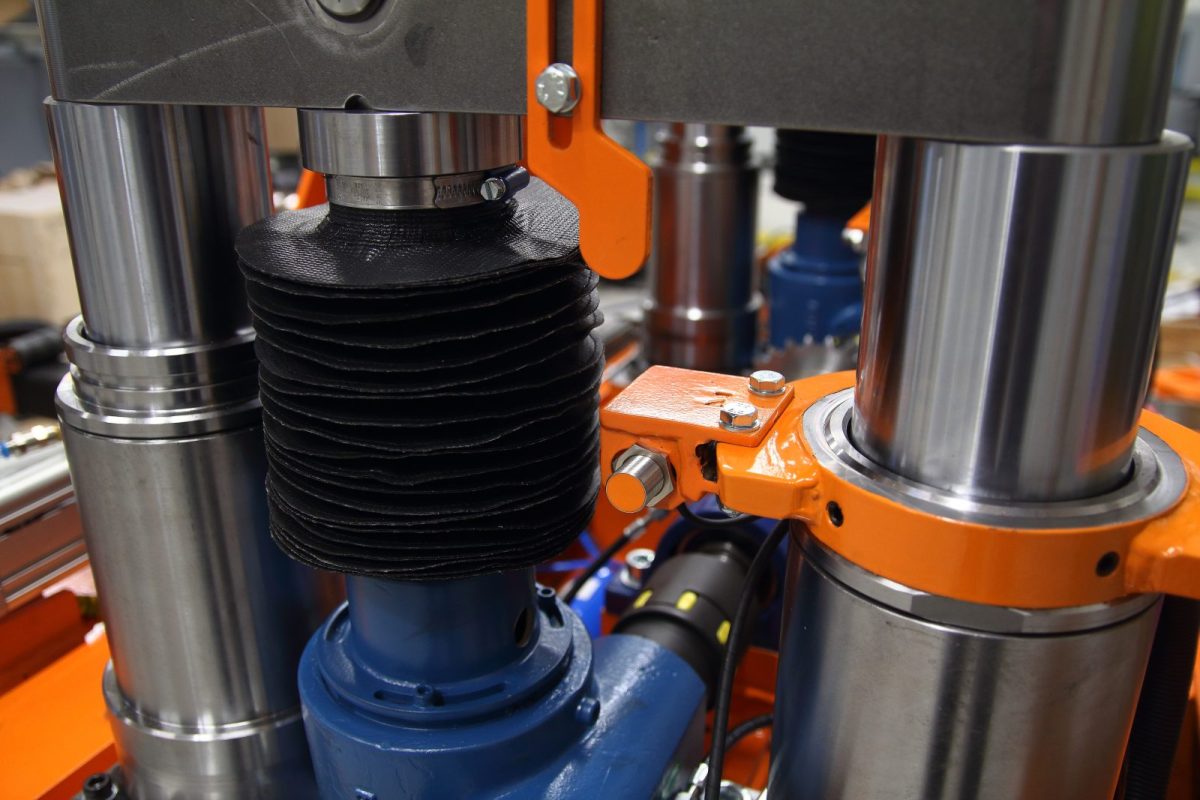

For a decade, Valtra and Lakome have been collaborating on continuously improving Valtra’s production efficiency.

Valtra and Lakome have collaborated to automate and enhance Valtra’s production processes. Their partnership has been mutually beneficial and productive for over a decade. Valtra is one of the world’s leading tractor manufacturers, specializing in the development and production of tractors and tractor components. Lakome is a provider of production efficiency and testing equipment, dedicated to improving various aspects of its clients’ production processes.

The collaboration has resulted in devices and testing systems that have enabled Valtra to increase the efficiency of its production lines and improve workplace safety. The equipment developed by Lakome is designed with durability and ergonomics in mind, enhancing user working conditions and reducing the risk of injury.

Vesa Hytönen, Development Engineer, AGCO Valtra:

”I have been working with Lakome and Samcons since 2012. Lakome has been a natural choice for a partner because of their extensive experience and understanding of Valtra’s processes. This experience has made it easy to rely on them when developing new models.”

What significant results have come from the collaboration between Lakome and Valtra?

”The improvements in production line tools have provided Valtra with a significant advantage. Ideas have been jointly brainstormed and initially designed, and then the work has been completed into a final product at Lakome.”

How satisfied are you with the collaboration?

”I have been very satisfied. The support is close by, as Lakome’s facilities are only about twenty kilometers away in Kellokoski. The collaboration has been close-knit, with project meetings held both on TEAMS and in person. It’s been easy to check on the project’s progress at Lakome’s facilities, and likewise, Lakome’s designers can verify details by visiting Valtra. The result of this approach is a high-quality device, with support continuing beyond the initial delivery and further development provided as needed after the final product has been delivered.”

Would you recommend Lakome to others?

”Yes, I would definitely recommend Lakome as a provider of solutions for production efficiency. Our collaboration with Lakome has worked excellently for Valtra. The partnership is flexible, straightforward, fast, and professional.”

AGCO Suomi Oy – Valtra traktorit

Moventas and Lakome have been working together for a decade to enhance various aspects of production and improve workplace safety. The collaboration has been smooth, mutually beneficial, and has yielded excellent results.

Moventas Gears Oy is a company that provides maintenance services for wind turbine drivetrain solutions. Moventas Gears Oy is owned by Flender GmbH.

Lakome is a supplier of production efficiency and product testing equipment, focusing on optimizing different areas of its customers’ production processes. Through their collaboration, Lakome has developed equipment that has enabled Moventas to enhance its production line efficiency and improve workplace safety. The equipment designed by Lakome is built to withstand demanding conditions while increasing durability and safety. This is particularly important for Moventas, as the wind turbine gearbox components they handle are heavy.

The collaboration has been highly successful, and Moventas and Lakome continue to work together to develop new solutions that contribute to the success of both companies.

How long have you been working with Lakome?

How would you describe the collaboration?

What problem has Lakome solved for Moventas?

What has been achieved through the collaboration, and how significant has it been?

How satisfied are you with the collaboration?

Would you recommend Lakome to others?

Moventas Gears Oy – Flender GmbH – https://www.flender.com/

Strong Trust and Long-Term Collaboration

Topi Vauhkonen, Valtra

“I have been working with Lakome for nearly 20 years—since 2005, when I started collaborating with Sami Savolainen shortly after the founding of Samcons Oy.”

Samcons Oy is the main owner of Lakome Oy.

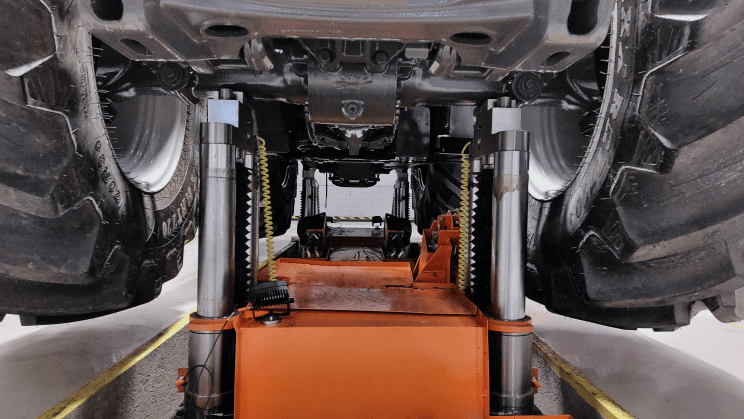

During the factory expansion in 2003, which included the finalization area, the current test-driving room was built, and four test stands designed by Samcons were installed. These stands lift the tractor off the ground, significantly reducing the noise caused by the rollers. Previously, with traditional rollers, tire noise was a major source of disturbance. After the upgrade, the gearbox sounds of high-speed machines could be more accurately observed without tire noise interfering with the testing.

This long-standing collaboration has built strong trust, and Vauhkonen states that there has never been any doubt about the success of their projects.

“When you know the people and have years of experience working together, the projects are bound to succeed—trust is solid,” Vauhkonen describes.

Vauhkonen emphasizes that the collaboration has been extremely smooth and flexible. Lakome’s commitment and adaptability have enabled the completion of projects within ambitious timelines. He notes that:

“Lakome has always been able to adjust to unexpected schedule changes to ensure that projects are completed on time.

They are quick to take action and willing to be flexible when needed. They are determined to see projects through to completion.”

The collaboration has brought significant improvements to Valtra’s operations. For example, in 2014, Lakome upgraded four hydraulic measurement units, improving measurement accuracy and safety. Additionally, Valtra’s test stands have been reinforced, and the testing structures have been upgraded thanks to Lakome’s development work.

“The hydraulic measurement unit renewal project brought a significant improvement. Lakome found the right solutions and equipment, enhancing efficiency and improving the quality and safety of the measurements.”

Vauhkonen expresses his great satisfaction with the collaboration and finds it difficult to identify areas for improvement. Perhaps regular “status check-ins” could be a useful way to ensure continuous development and alignment.

“It’s hard to imagine how our collaboration could be improved. Everything works well, and the projects have delivered significant results.”

The trust built over the years and the success of past projects provide a strong foundation for continued collaboration in the future.

AGCO Suomi Oy – Valtra Tractors

Easy and Reliable Collaboration

Jyrki Keto, Production Engineer

Valtra Oy, Drivetrain Factory

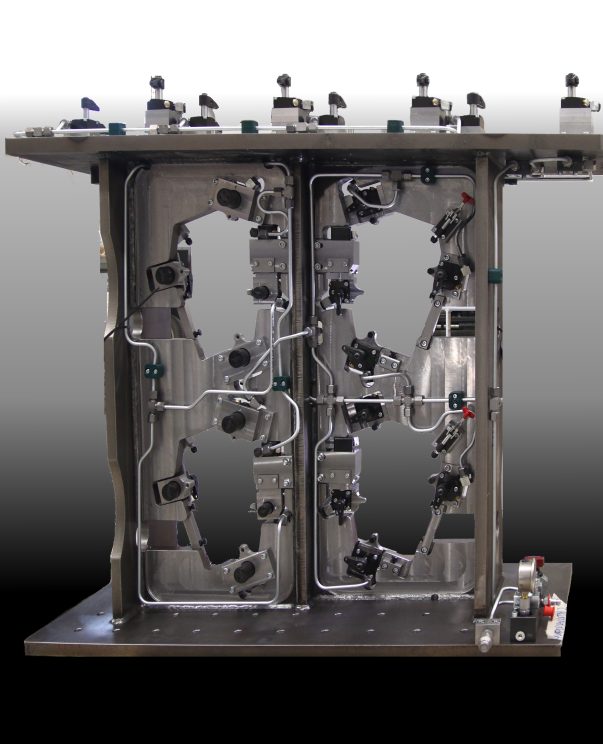

Over the past year, Lakome Oy has supplied Valtra with several machining fixtures essential for various stages of drivetrain component processing.

The collaboration has been excellent—smooth and flexible. Lakome has been proactive, and if something was unclear, they immediately reached out to clarify and find solutions.

“The collaboration has been excellent.”

The most important solution was finding a reliable supplier for machining fixtures. It was not easy to find a manufacturer in Finland, but fortunately, we discovered one close by.

Machining fixtures are essential to our operations. Lakome’s solution has been the best possible choice, as our own resources would not have been sufficient. This has been an extremely significant partnership.

“The most important solution was finding a reliable supplier for machining fixtures.”

AGCO Suomi Oy – Valtra Tractors

#Valtra

#Manufacturing

#Machining

#Lakome

#ReliablePartnership

#ProductionEfficiency

Lakome’s high level of professionalism is highly appreciated.

Erki Ala

Manager at AS Dale LD.

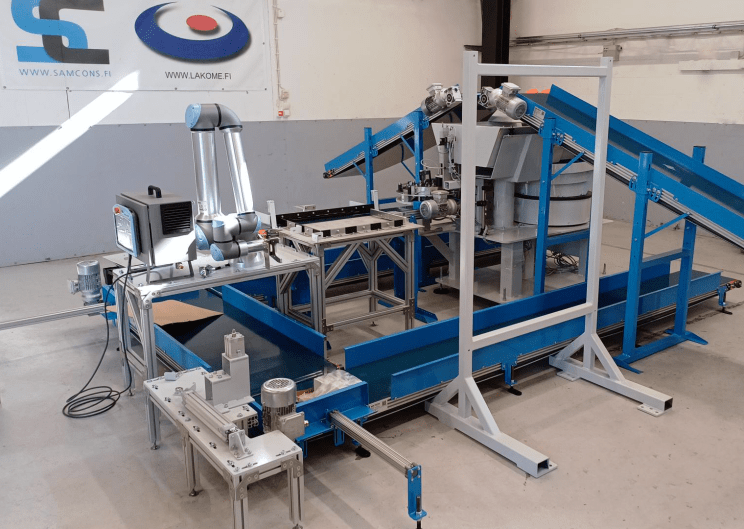

The automated packing line provided to Dale LD. AS by Lakome is the first collaboration project between the two companies. Dale was looking for a solution to automate the most labour-intense section of its plastic injection moulding process and Lakome was able to provide a tailor-made solution. The entire procurement process from designing to physically installing the equipment went smoothly and the partnership has been mutually beneficial and productive.

Dale is an Estonian manufacturer located in a scarcely populated rural area and they specialise mainly in offering injection moulding services based on the principle of subcontracting. Lakome is a provider of production optimization and testing equipment, focusing on improving various aspects of their clients’ production processes.

…allows Dale enhance the efficiency of their production lines and diminish the amount of manual labour…

As a result of this collaboration, equipment has been developed that allows Dale to enhance the efficiency of their production lines and diminish the amount of manual labour, which in turn means improved cost-efficiency and decreased dependence on the scarce supply of skilled workers in the rural area where Dale operates. Lakome’s solution is tailor-made to suit the very specific needs of this section of Dale’s manufacturing. Lakome’s high level of professionalism is highly appreciated.

Dale and Lakome are planning to continue their cooperation…

The collaboration is ongoing as Lakome also provides post-installation remote problem-solving for the automated packaging line. Dale and Lakome are planning to continue their cooperation, striving to develop new solutions that advance the success of both companies.

AS Dale LD- Suomeksi

AS Dale LD- In english