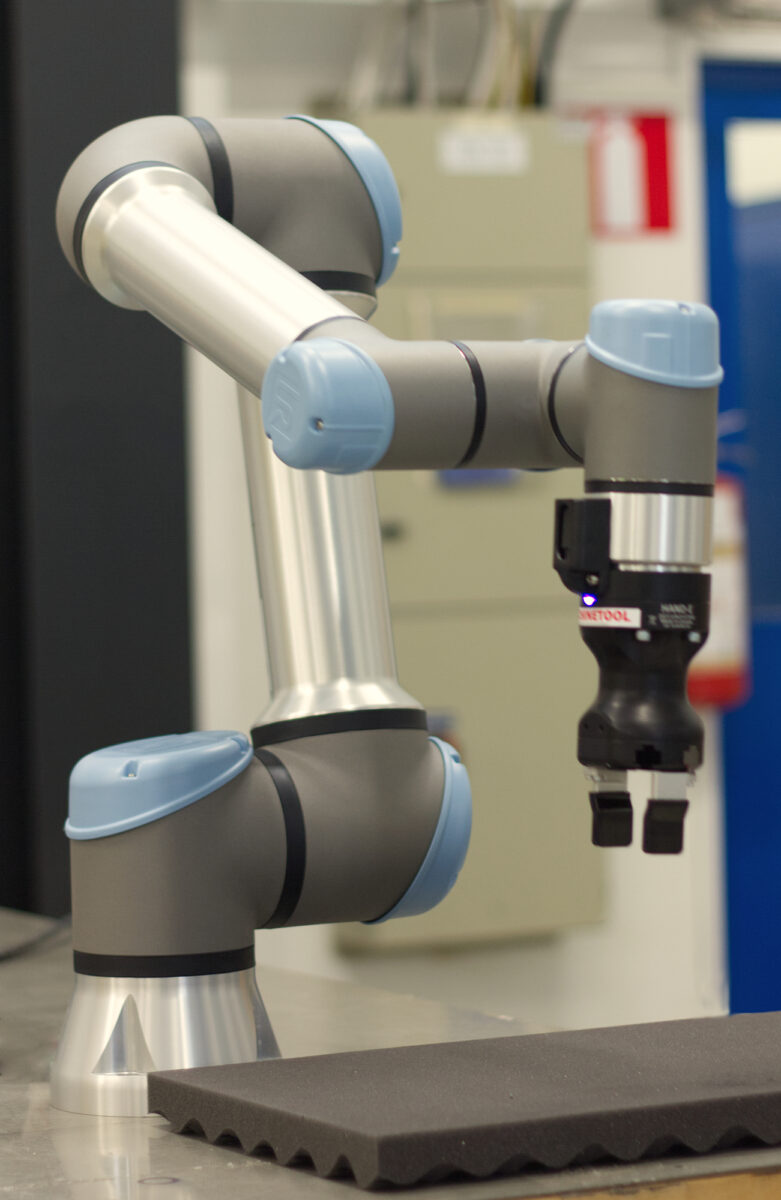

Cobots lend a helping hand in production

We deliver customised collaborative robot systems across industries.

We deliver customised collaborative robot systems across industries.

We design and deliver pre-assembled and tested collaborative robot and traditional robot systems for all tasks and environments. Ready-made robot cells are an ideal solution when the production process is repetitive. Collaborative robots are also known as cobots. Cobots are intended for spaces where people are also working at the same time.

In comparison to humans, who are restricted by their physiology, robots exhibit higher levels of accuracy, speed, and endurance in repetitive tasks. The use of suitable cobots enables longer and faster production cycles.

Robots repeat their task without errors and with tighter tolerances. This enables a more precise production process, leading to enhanced product quality and workmanship.

Cobots can work in the same spaces as humans and use their sensors to prevent collisions and damage. The movements of cobots are predictable and repetitive, which reduces the risk of work-related accidents.

Click the button on the right, and we’ll schedule an appointment to discuss your needs.

A collaborative robot, cobot, is a type of robot designed to work together with humans on industrial or other tasks. What sets them apart from traditional robots is their enhanced ability to operate safely near humans and various environments without posing a safety risk.

Collaborative robots offer new opportunities for industrial automation and digitalisation, improving efficiency and productivity in areas such as assembly, packing products in transport units and moving objects. We have gathered extensive experience with various robot manufacturers and use top-of-the-line products from leading cobot manufacturers.

Collaborative robots are an important part of modern industrial digitalisation, and using them use benefits industrial companies in many ways. Cobots improve the production efficiency and output of the company, help make quality improvements and reduce errors.

Collaborative robots can work together with humans and therefore offer a new way of carrying out industrial production processes. A collaborative robot and a human can work safely on the same production line. They can be used to perform complex and demanding tasks that people cannot perform alone or find difficult to control. Collaborative robots are especially useful in handling complex and demanding production processes that require precise and fast reactions.

Collaborative robots also reduce workers’ exposure to tasks and substances that are considered hazardous or harmful to health. This improves occupational safety and reduces the risk of illness and injury.

Collaborative robots offer new opportunities for the automation and digitalisation of industrial processes. They are able to collect and analyse data in real time and support decision-making by providing important information to company management. This boosts the company’s competitiveness and helps the company react quickly to changes in the market.

Collaborative robots are also efficient and save energy, which makes them a sustainable and economical option for industry needs. Robots also contribute to a reduction in material and energy consumption, making them an environmentally friendly option.

In industry, the use of cobots has many advantages that cannot be achieved with other methods. Cobots improve efficiency, reduce errors, improve occupational safety and provide important information to company management.

We provide reliable, quick and friendly service across industries. We foster a close collaboration with our partners, actively listening to their wishes and tailoring our operations to meet their specific needs.

Tell us what your production-related challenges are and we will come up with a solution to tackle them!

Let’s have a meeting. We’re Here to Help you.